JAKOŚĆ i ŚRODOWISKO

Zadowoleni klienci są priorytetem w naszej firmie. Obok absolutnej elastyczności decydującą rolę odgrywa jakość naszych podzespołów i urządzeń. Tylko dzięki najlepszym wynikom i wysokim standardom jakościowym zapewniamy sobie długotrwałe relacje z naszymi klientami.

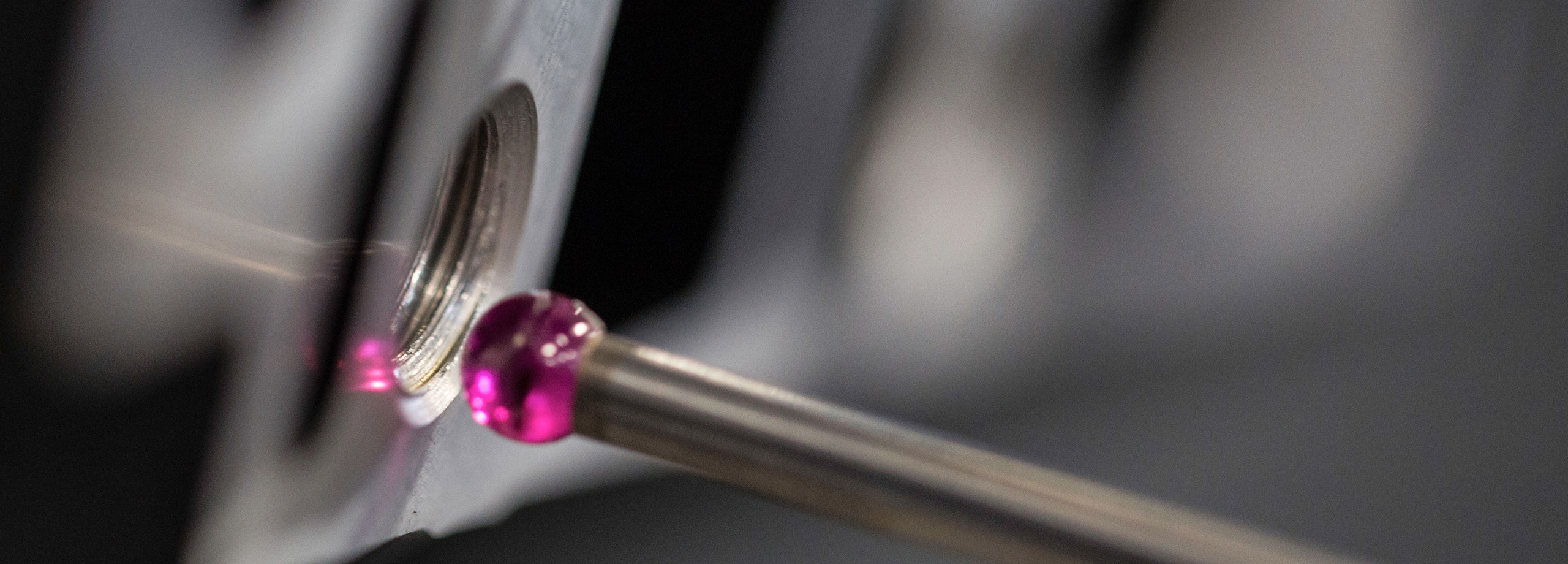

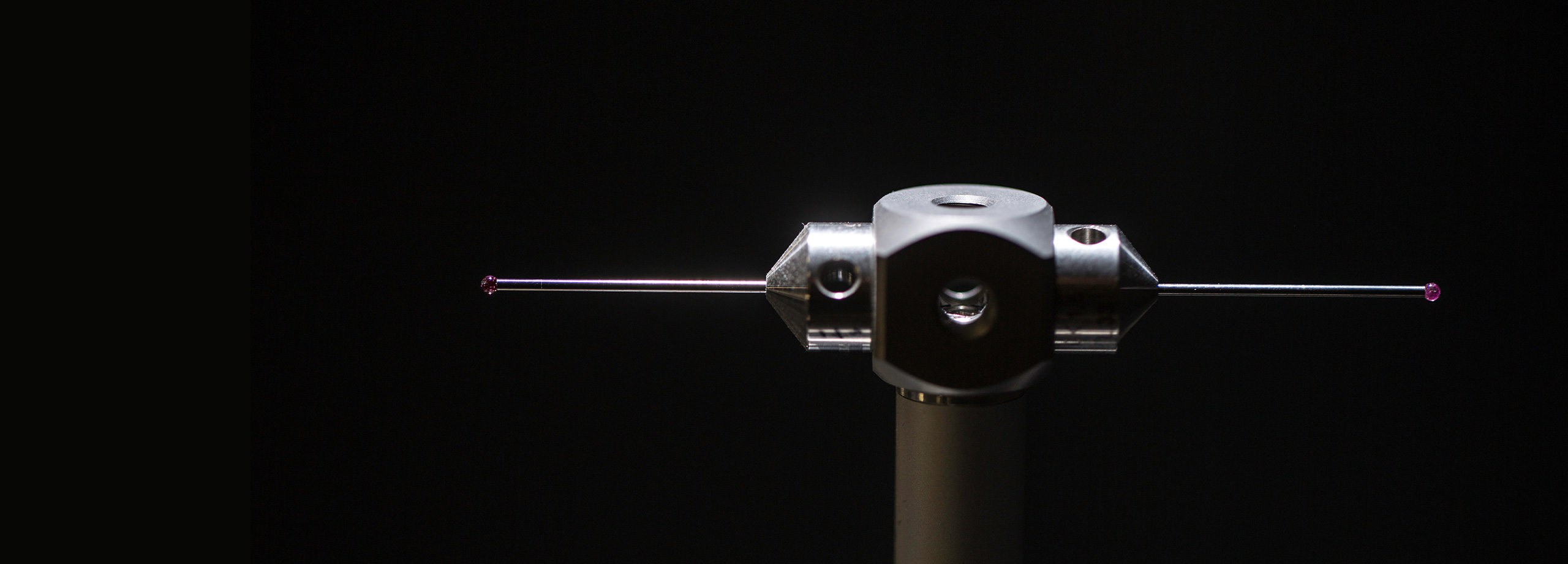

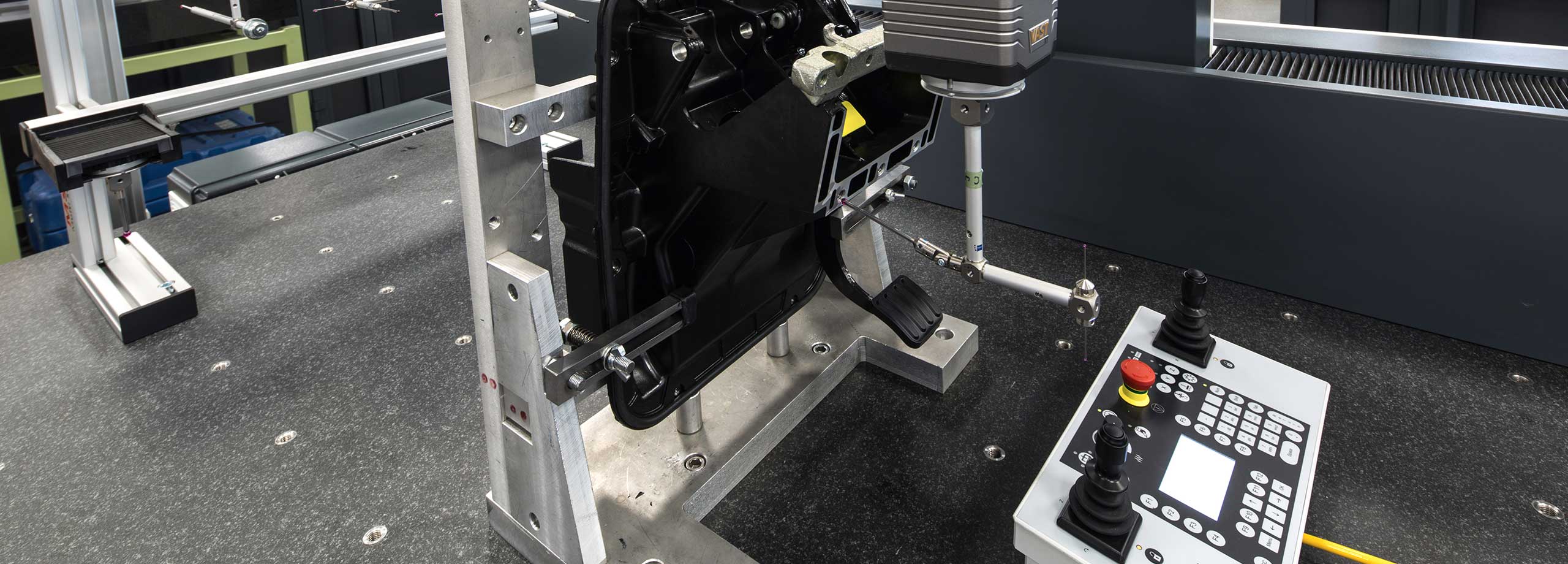

W celu uzyskania dokładnych wyników i utrzymania jakości naszych produktów na najwyższym poziomie, w naszej firmie stosowane są najnowocześniejsze i najbardziej precyzyjne systemy pomiarowe i badawcze. Aby zawsze osiągać jak najlepsze korzyści dla klienta i spełniać nasze wysokie standardy jakościowe, pracujemy zgodnie z systemem zarządzania jakością zintegrowanym z procesem. Dzięki temu możemy jak najwcześniej wykryć potencjalne usterki, wyeliminować je i wykluczyć na przyszłość.

Oczywiście posiadamy certyfikaty IATF 16949 i ISO14001.

„To, co robimy dzisiaj, decyduje o tym, jak będzie wyglądał świat jutro“

Marie von Ebner-Eschenbach

Jako przedsiębiorstwo, w którym zachodzą procesy energochłonne, odpowiedzialność wobec środowiska i społeczeństwa jest podstawą naszych działań. Na pierwszym miejscu jest bezpieczeństwo naszych pracowników, a następnie wymóg ochrony naszych zasobów i zrównoważonej produkcji. Ponieważ na dłuższą metę wszyscy korzystamy tylko wtedy, gdy natura jest w równowadze. Nasz sukces i rozwój zawdzięczamy ludziom, którzy stoją za SFB Polska. To one stanowią nasz największy potencjał i to za nie ponosimy odpowiedzialność.

Prowadzimy stały dialog z naszymi pracownikami na temat jakości, ochrony środowiska i bezpieczeństwa pracy.

Przestrzeganie i realizacja wszystkich wymogów prawnych oraz uwzględnianie wymagań naszych klientów są dla nas czymś oczywistym. Zwracamy szczególną uwagę na jak najbardziej ekonomiczne i efektywne wykorzystanie energii.

Poprzez ciągłą wewnętrzną i zewnętrzną ocenę naszego systemu zarządzania oraz podejmowanie odpowiednich działań, osiągamy proces ciągłego doskonalenia i dalszego rozwoju.